TECHNOLOGY

- Optical Emission Spectroscopy (OES) is a real-time technique perfect for non-intrusive plasmabased process characterisation, diagnostics and monitoring. The plasma process is not disturbed; thus, issues related to harsh process conditions can be overcome. The technique is used for:

- plasma process characterisation Te, ne, EEDF, EEPF

- plasma process diagnostics, trouble-shooting,

- plasma process deviation, drift monitoring,

- plasma process recognition, finger-printing,

- creating a digital twin of the plasma process and predictive maintenance.

- OES is rapid, precise and sensitive to small process changes, thus an ideal tool in critical manufacturing environments.

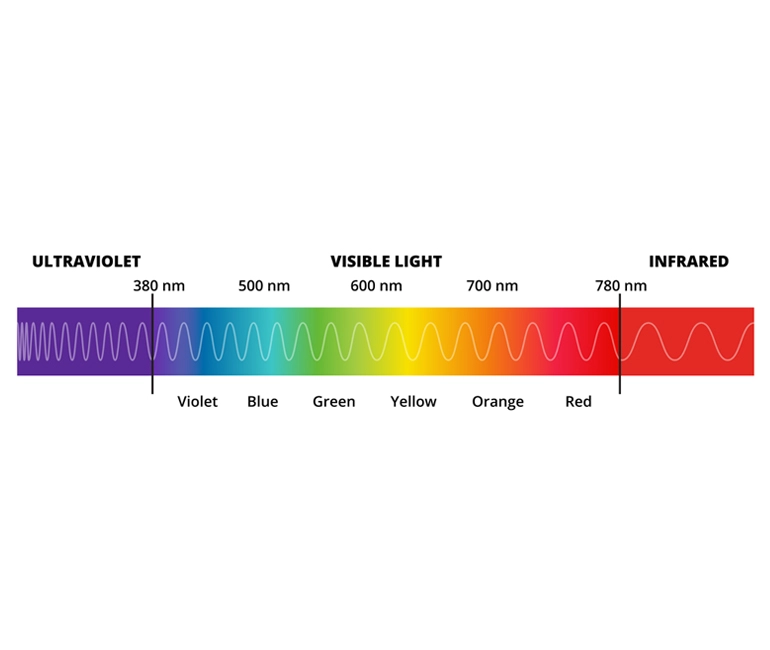

- OES is typically practised in the 200 to 1040 nm range with spectrometer resolution of 0.1 to 6.0 nm, the range and resolution being application-dependent.

- OES enables to determine what elements are present in the plasma by collecting the emitted light and analysing its spectrum in the UV-VIS-nIR range.

- OES enables process engineers to monitor the plasma process and detect events of critical importance. OES yields valuable process data that can be used for predictive maintenance in manufacturing and creating digital twins for simulation and testing.

HOW WE APPLY IT

Nova Fabrica OES systems fuse seamlessly with production lines in intelligent factories. Detectors featuring 0.15 - 0.5 nm optical resolution and bespoke range sense one or multiple plasma emission lines. Passive or active temperature control, C-Sensor™, wavelength calibration, radiometric calibration and intensity non-linearity correction enable precise, accurate, and reproducible OES plasma characterisation, plasma emission monitoring, process development, optimisation, monitoring, control and quality assurance. Radiometric calibration of the complete optical path using an optional certified Uniform Light Source enables Inteleg® OES systems to make accurate measurements traceable to national standards.

CHALLENGE

Micro-fabricartion technologies are becoming increasingly complex as performance and environmental requirements change. You develop new materials and layer stacks to address the current needs. You cannot calculate the basic plasma parameters such us Te and Ne. You find it hard to precisely repeat the plasma process condition, determine drifting process, detect a disturbance or a leak. Enhancing your existing and new tool’s process monitoring and control capabilities is critical to increasing product value, tool yield and reducing the overall ownership cost.

SOLUTION

Lift your processes to the next level of performance and productivity. Inteleg® OES solutions provide precise real-time process monitoring and spectral data with the reliability needed for modern 24/7 production. Process engineers and technologists can leverage new capabilities with unprecedented speed, measurement timing precision, and control accuracy.

Unique and customer-driven solutions can drastically increase performance. Inteleg® OES solutions offer an ever-growing envelope of advantages, ranging from advances in thin-film materials to productivity increases and scrap prevention.

BENEFITS

- Embedded atomic and molecule lines database

- Process reproducibility and long-term stability

- Automated calibrations system health checks

- Dramatic process improvements

- Scrap and downtime prevention

- Easy installation and OEM integration

- Rugged design, single compact unit

- Cost efficiency