Meet us:

There are no up-coming events

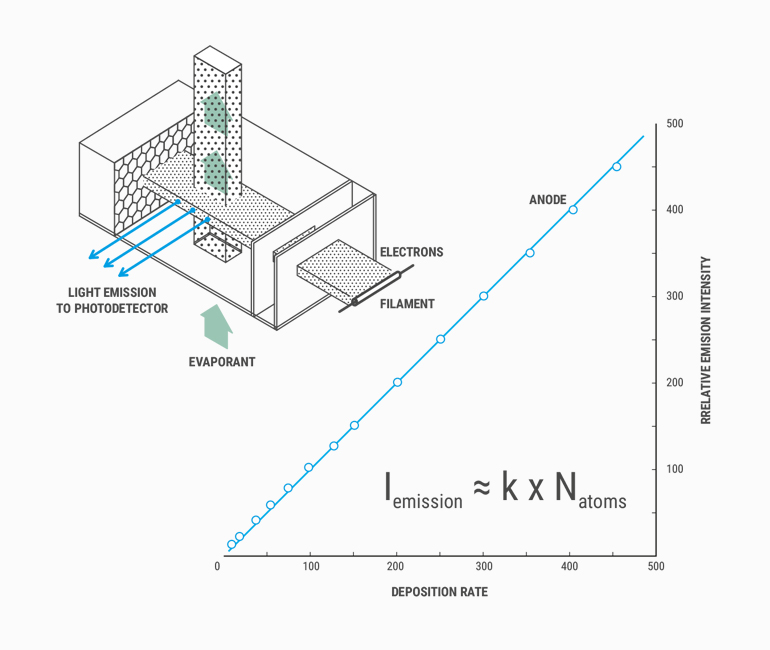

Nova Fabrica Inteleg®S EI systems fuse seamlessly with production lines in intelligent factories. They are deployed to evaporative PVD, e.g. EB PVD and thermal PVD, process environments that require:

Real-time deposition rate monitoring monitoring, process monitoring, process condition recognition, and closed loop control help to improve performance and maximise yield.